Advanced Alloy Shields™ custom manufactures reusable hard cover thermal insulation systems that are molded to fit directly over hot engine components, up to 3000° F. (1649° C.). Since 1972 we have worked with military and aerospace industries and is one of the most qualified companies for extreme heat control.

Our experience with leading military defense suppliers United Defense, Norcatec and Relli depend on us for solutions to heat issues for equipment from Aircraft, Tanks and Armored Vehicles, to power generation and other specialty equipment.

Why Choose Advanced Alloy Shields?

Our #1 priority is to create an insulation system that performs beyond the expectations of our customers. Our advanced ability, design and materials are key factors that help set us apart as leaders in the insulation industry.

Advanced Ability. Each part we manufacture requires that individual molds be made, which are necessary to manufacture such form-fitting and detailed product. With drawings or physical parts, we can custom make tooling, in-house, that meet the exact requirements for your application. This ability expedites the design and fabrication process and allows us to pass savings on to the customer.

Advanced Design. We utilize 3D CAD design software and computerized cutting tables to ensure accuracy and consistency on high-production runs. Product you order two years from now will look and perform the same as product we make for you today.

Extra care is given to ensure optimal performance. Aerodynamic customization and advanced ridgidizing techniques may be used to help achieve a desired effect.

Advanced Materials. We have searched the world for the most advanced materials available and use only those that satisfy our highest standards. We use top-of-the-line alloy metals such as Inconel, Stainless Steel and Aluminum. Long-lasting insulation materials such as high-grade Fiberglass, Silica, Ultra Flex, Min-K and Flex Wrap are just a few of the materials we use to provide solutions that are guaranteed to meet your needs.

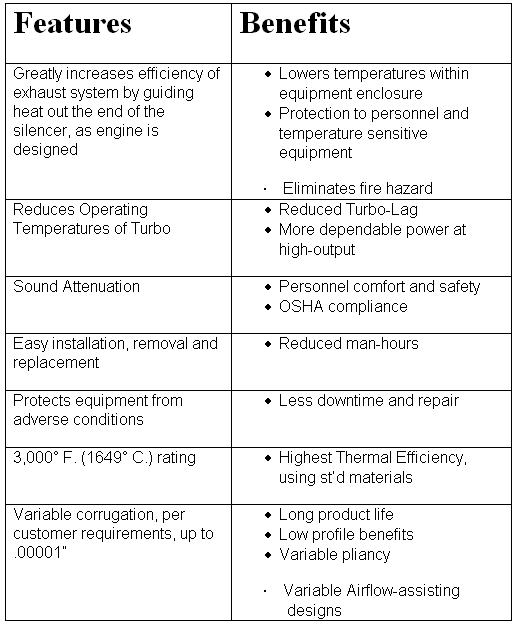

Value Added Benefits:

Quality Assurance. Advanced Alloy Shields’ internal Quality Control Department goes beyond what is normally expected by providing consistent quality and measurability of performance. Our stringent inspection requirements catch defects, sharp edges and design inconsistencies well before they have a chance to be shipped.

Service is one factor often not provided in industrial manufacturing; Advanced Alloy Shields™ is the exception. We have established relationships with our customers and take enormous pride in each product we send out. We will work with you to assure that your product is exactly what you need as well as complete after-sale product support.

Our facilities and processes are streamlined to assist you in meeting your demanding schedules.

Shipping and Packaging conforms to all commercial and military standards. We can set up a JIT or EDI inventory system that will assure the product you need, when you need it.

The quality of our products and personnel meet the following Military Specifications and Standards: